Comparing P43 and P47 Phosphors for Imaging Applications

Comparing P43 and P47 phosphors for imaging applications is vital for researchers, laboratories and manufacturers who rely on precision results. The choice between these two phosphor types can determine whether an imaging system delivers high sensitivity, rapid frame rates, or consistent clarity across repeated tests. At Analytical Components, we provide expertly coated phosphor screens that are designed to meet the demanding requirements of advanced imaging, ensuring that every screen we supply delivers both reliability and performance.

Why Phosphor Choice Matters

Phosphor screens play a central role in scintillation. When X rays or electrons strike the screen, the phosphor layer emits visible light that can be captured by cameras or detectors. The properties of the phosphor directly influence how much light is emitted, how long that light persists, and the colour of the emission. This means the choice of phosphor is not a minor detail but one of the most important decisions when specifying a scintillator screen. At Analytical Components, our expertise lies in providing the right phosphor for the right application, supported by our ISO 9001 certified cleanroom manufacturing.

Understanding P43 and P47

When comparing P43 and P47 phosphors for imaging applications, the most noticeable difference lies in their decay times and light output.

- P43 phosphor emits a green light at around 545 nanometres and is known for its strong brightness and efficiency. It provides an excellent signal for detectors but has a relatively longer decay time, typically around one millisecond. This makes P43 highly effective for imaging setups that prioritise light yield and can tolerate slightly slower response times.

- P47 phosphor emits in the blue white region at around 400 nanometres. While its brightness is lower than P43, it has an exceptionally fast decay time, often in the range of tens of nanoseconds. This property makes P47 an outstanding choice for high speed imaging, where avoiding afterglow and preventing overlapping signals are essential.

At Analytical Components, we offer both P43 and P47 phosphors applied with precision coating techniques to ensure uniformity and durability, giving you confidence in the performance of your imaging system.

Decay Time and Imaging Speed

For many users, the deciding factor in comparing P43 and P47 phosphors for imaging applications is decay time. In fast imaging environments, even a small amount of persistence can cause afterimages or ghosting that compromise results. This is why P47 is so often chosen for experiments such as Particle Imaging Velocimetry or time resolved microscopy. On the other hand, if sensitivity is more important than speed, P43 provides higher efficiency, producing a stronger and brighter signal that makes detection easier in low light conditions.

At Analytical Components, we help clients analyse the trade offs between brightness and speed. Our team works closely with research groups, medical imaging specialists and industrial partners to determine which phosphor delivers the most accurate results for their systems.

Spectral Output and Detector Sensitivity

The emission colour of each phosphor also matters. Detectors often have peak sensitivities at particular wavelengths. P43, with its green emission, is very well suited to many CCD and CMOS detectors, which often have high sensitivity in the green region of the spectrum. P47, with its blue emission, may require detectors that perform better at shorter wavelengths. This means that the decision is not just about decay time but also about how the phosphor interacts with the rest of the imaging system.

Our phosphor screen scintillators at Analytical Components can be manufactured with additional coatings, such as Indium Tin Oxide or reflective aluminium, to enhance performance and ensure that the maximum amount of emitted light is directed towards the detector. This level of customisation ensures that whether you select P43 or P47, the screen you receive will perform exactly as you need it to.

Matching the Phosphor to the Application

When comparing P43 and P47 phosphors for imaging applications, the final choice often comes down to the context in which the screen will be used.

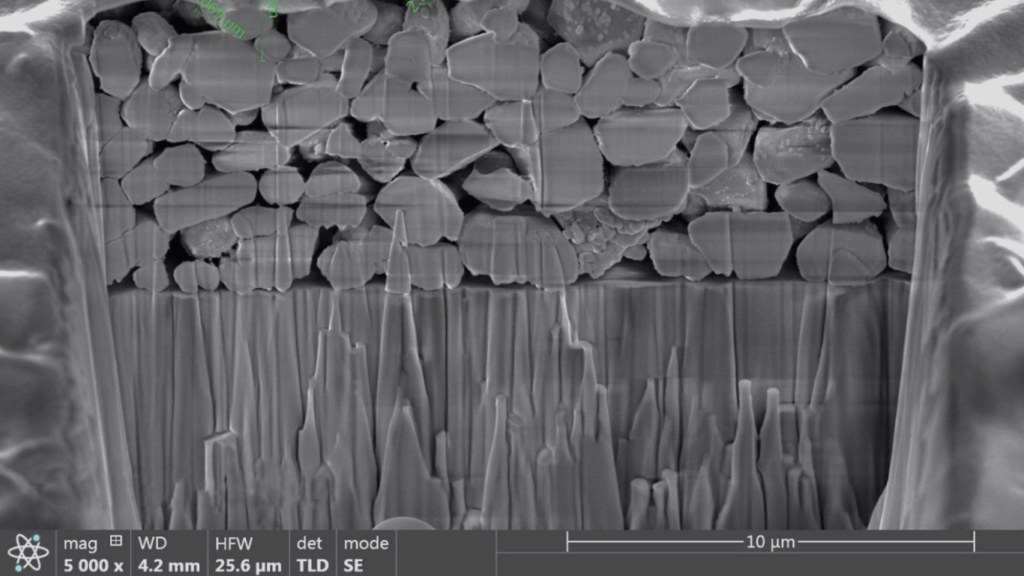

- P43 is the better choice for applications that require longer exposure times, higher sensitivity and brighter images. It is commonly used in systems where image quality and clarity matter more than frame rate, such as certain forms of X ray imaging or slower scanning electron microscopy setups.

- P47 is the phosphor of choice for high speed imaging and time resolved studies. Its ultra fast decay ensures that each frame is clean, without interference from the previous exposure. This makes it indispensable in applications like fast electron microscopy or high frame rate optical imaging.

At Analytical Components, we understand that no two applications are identical. That is why we offer both phosphors across a range of substrates including glass, fibre optic plates, silicon and metal, ensuring you can build a scintillator screen that is perfectly suited to your needs.

The Importance of Cleanroom Manufacturing

Another critical factor in performance is the quality of the coating itself. Even the best phosphor can fail if it is not applied with consistency and precision. At Analytical Components, we operate from a Class 10,000 ISO 7 cleanroom, accredited to ISO 9001:2015 standards. This environment ensures that every screen we produce has a uniform layer of phosphor, free from contamination or inconsistencies. For our clients, this means dependable, repeatable results and confidence that their imaging equipment will perform at its best.

Supporting Innovation and Custom Development

We also recognise that many clients require bespoke solutions. Some projects may demand specific coating thicknesses, additional conductive layers or unusual substrate sizes. At Analytical Components, we specialise in providing both one off prototypes and larger production runs. By working closely with your research or engineering team, we ensure that whether you need a single screen for testing or a full batch for integration, your requirements are fully met.

Get In Touch

Comparing P43 and P47 phosphors for imaging applications is about more than simply choosing between green and blue light. It is a decision that influences speed, brightness, clarity and the overall performance of your imaging system. P43 provides strong light yield and is ideal for high sensitivity applications, while P47 offers ultra fast decay times that are essential for high speed imaging. At Analytical Components, we provide both options, manufactured with precision and tailored to your exact needs. With decades of combined experience and a commitment to quality, we are the trusted partner for research groups and industries that require scintillator screens they can depend on.

Need expert advice? Get in touch today via our contact form, email us at info@analyticalcomponents.uk, or call us at +44 (0) 1424 850004 to discuss your project requirements. Whether you require phosphor screens for microscopy or X-ray scintillators for imaging applications, we can help.

Enhance your imaging capabilities with precision-engineered scintillators from Analytical Components.