How Reflective and ITO Coatings Enhance Light Output

Understanding how reflective and ITO coatings enhance light output is essential to producing high-performance scintillator and phosphor screens. These coatings define the brightness, clarity and efficiency of modern imaging systems. It plays a central role in how light is captured, redirected and transmitted to the detector. At Analytical Components, our precision manufacturing processes and ISO-certified cleanroom environment ensure that both reflective and ITO coatings deliver exceptional optical and electrical performance for a wide range of scientific applications.

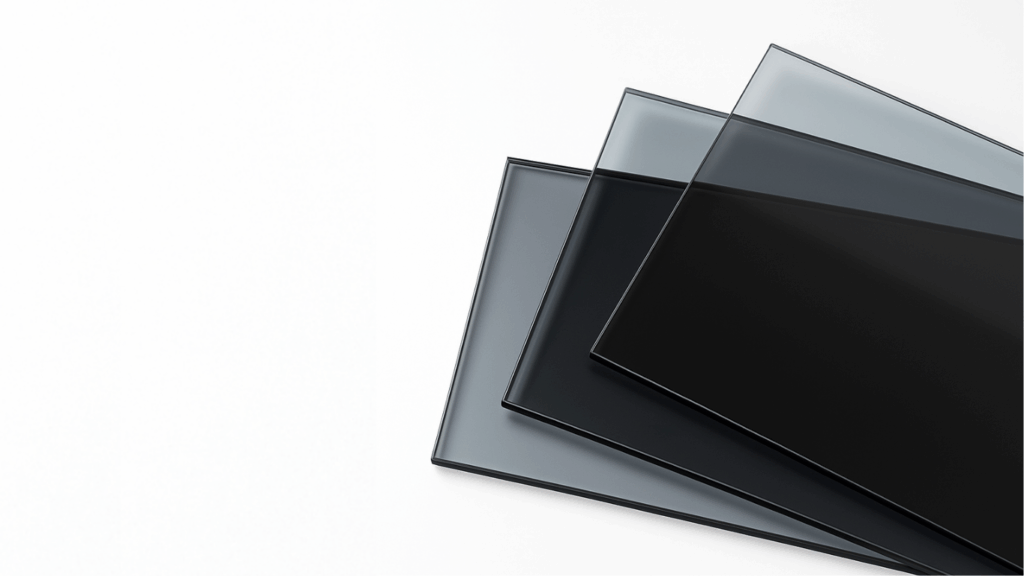

Understanding Reflective and ITO Coatings

Reflective and ITO, or Indium Tin Oxide, coatings each serve a distinct function in the structure of a phosphor screen. A reflective layer, often made from evaporated aluminium, is designed to redirect light. This would otherwise be lost through the rear of the phosphor. This helps maximise signal strength and brightness.

An ITO coating, by contrast, is a conductive but transparent layer. It allows charge to dissipate without blocking visible light. This property makes it essential for electron-based imaging systems such as Electron Backscatter Diffraction and Transmission Electron Microscopy.

Through careful control of coating thickness and surface preparation, Analytical Components achieves a balance between conductivity, reflectivity and optical precision that enhances imaging performance across every product line.

How Reflective Coatings Improve Brightness

Reflective coatings play a key role in boosting the apparent brightness of a phosphor screen. When incoming radiation or electrons excite the phosphor, light is emitted in all directions. Without a reflective layer, a large portion of that light escapes backwards, reducing output efficiency. Applying a thin, uniform aluminium coating redirects this light forward, increasing signal intensity without the need for thicker phosphor layers.

At Analytical Components, aluminium coatings are applied in a cleanroom to achieve extremely high reflectivity and consistency. Each coating is carefully monitored to maintain optical uniformity and prevent scattering. This precision ensures bright, stable images and reliable calibration over extended operational use.

The Advantages of ITO Coatings in Electron Imaging

While reflective coatings increase optical brightness, ITO coatings are essential for maintaining image stability in electron-based systems. In environments where electron beams interact with phosphor surfaces, static charge can accumulate, distorting the image or reducing clarity.

An ITO layer provides an effective way to dissipate that charge while allowing light to pass freely through to the detector. Its combination of transparency and conductivity makes it ideal for sensitive scientific instruments. At Analytical Components, our vacuum deposition techniques produce uniform, finely controlled ITO layers that ensure electrical performance without compromising optical quality. This meticulous attention to coating integrity is a hallmark of our manufacturing process.

Balancing Coating Thickness and Optical Performance

Optimising how reflective and ITO coatings enhance light output depends on precise control of coating thickness. If a reflective layer is too thick, it can scatter light and reduce sharpness. If an ITO layer is too thin, it may not conduct efficiently across the surface.

Our manufacturing process allows coating parameters to be tailored for each application. X-ray scintillator screens may require thicker reflective coatings to achieve maximum brightness, while electron imaging screens benefit from thinner, highly transparent ITO layers. Every product is tested for optical consistency, adhesion and performance before leaving our facility, ensuring reliability from first use.

Applications Across Imaging and Detection

Reflective and ITO coatings are integral to performance across a wide spectrum of imaging technologies. When X-ray imaging, reflective coatings increase light yield and enhance contrast. In electron microscopy, ITO coatings prevent charging effects that can interfere with precision imaging. In medical, industrial and scientific detectors, both coating types work together to maximise light capture and maintain consistent results.

By continuously refining how reflective and ITO coatings enhance light output, Analytical Components supports the development of instruments that deliver higher accuracy, sharper resolution and improved efficiency.

Cleanroom Manufacturing for Maximum Precision

The environment in which coatings are applied is just as critical as the coating materials themselves. Contamination can lead to scattering points or uneven surfaces that reduce optical efficiency. To avoid these issues, all coatings at Analytical Components are applied in an ISO 9001 certified cleanroom environment.

This level of precision ensures the highest possible quality in both reflective and conductive coatings, with consistent results across every production batch. Our cleanroom procedures, advanced vacuum systems and rigorous quality checks enable us to meet the demanding standards expected by leading manufacturers and research institutions.

Continuous Development in Coating Technology

The science behind how reflective and ITO coatings enhance light output continues to evolve alongside advances in detector and imaging technology. At Analytical Components, we are committed to ongoing research and development. We are always exploring new coating techniques and materials to achieve superior performance. Our ability to work with a range of substrates, from glass and fibre optic to silicon and metal, allows us to deliver tailored solutions for every imaging challenge.

Whether you need high-reflectivity aluminium coatings for X-ray detection or finely tuned ITO coatings for electron imaging systems, we can provide the expertise and precision required for outstanding optical performance.

Conclusion

Producing coatings that enhance light output demands precision, expertise and an understanding of how each layer interacts with light and charge. Reflective and ITO coatings are not simply surface treatments. They are integral to the performance of the entire imaging system, from X-ray detection to electron microscopy.

At Analytical Components, we combine deep technical knowledge with cleanroom manufacturing and responsive customer support. Our coatings are developed to the highest standard, ensuring every scintillator or phosphor screen we produce delivers exceptional optical and electrical performance. If you would like to discuss how our reflective or ITO coatings can support your next project, we’re always ready to help.

Get in touch today via our contact form, email us at info@analyticalcomponents.uk, or call us at +44 (0) 1424 850004 to discuss your requirements.